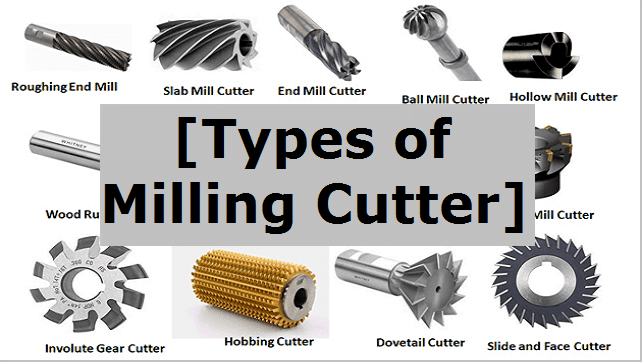

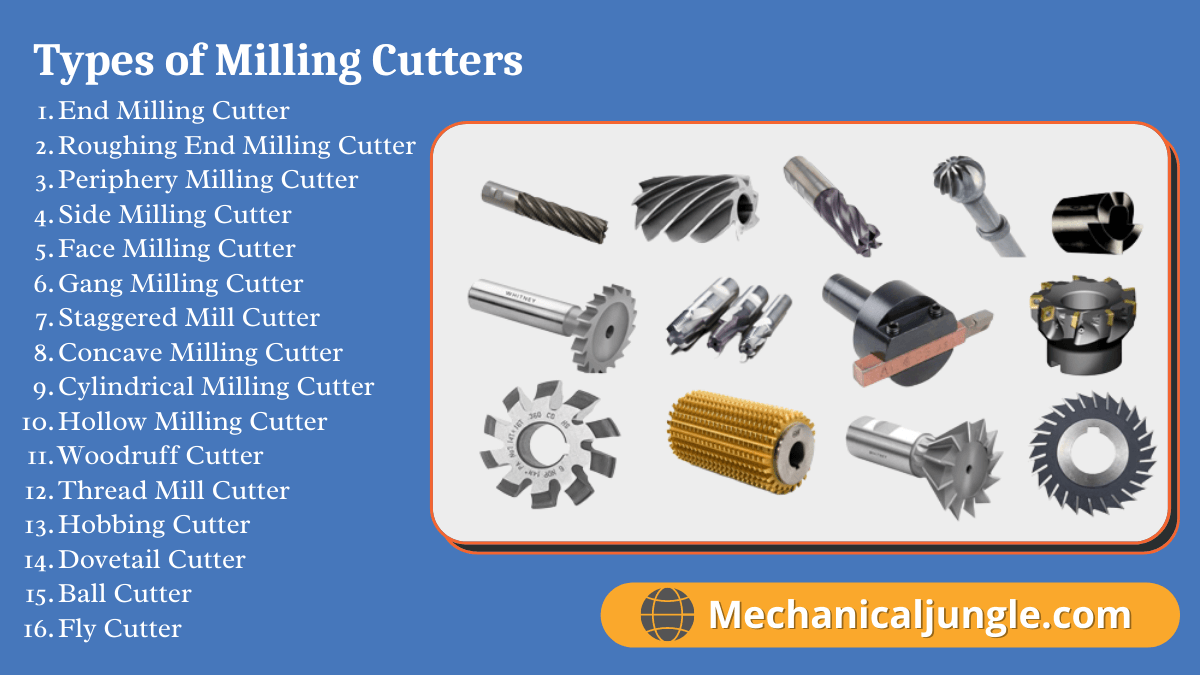

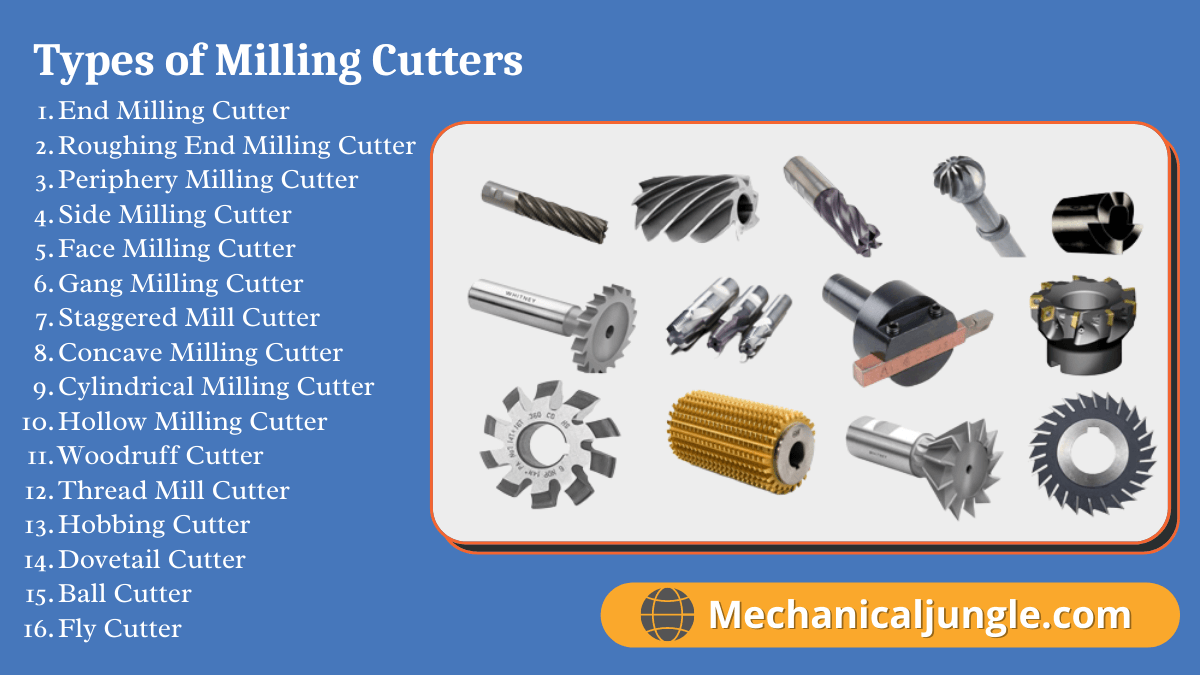

Describe the Different Types of Cutters Used in Milling Operations

Milling uses rotating cutters to remove material unlike turning operations where the tool does not spin. The milling operation creates small metal cuttings called swarf that cause.

Milling Cutter Definition Types In Detail Geometry Material Notes Pdf

Confirm e-mail address Please re-type your e.

. Wrenches screw drivers etc to adjust tooling or fixtures for set up changes or quality adjustments. Depending on the situation a combination of two or more safeguards may be needed to keep workers safe. There is also a skiving tool that can be used for light finishing cuts.

0 0 0 0 0 0 0. Describe the types nomenclature and use of milling cutters. Form tools can be made of cobalt.

0 0 0 0 0 0 0. Please note that one e-mail address can only by assigned to one active account. Different mould construction methods are used in the industry.

0 0 0 0 0 0 0. ComRod Size-TPI RH High-Speed Rod Size-TPI RH High-Speed Rod Size-RH TPI High-Speed Pipe Size Used in Die Head Weight. Be sure to choose extension cords wisely by choosing a heavy gauge wire by following the chart that we have provided.

This section covers the types of machine guarding available and the situations where it is generally used. Lathes are used in woodturning metalworking metal spinning thermal spraying parts. 0 0 0 0 0 0 0.

0 0 0 0 0 0 0. Six credit hours are awarded for successful completion of this subcourse. If youre looking for classic Chevy truck parts or classic GMC.

Produce various types of products used in the Medical Device industry Ensure production requirements are met product quality is maintained machine maintenance is adhered to and safety rules are followed Use diverse types of hand tools ie. 71 Types of guards that isolate the. On these machines the cutting tools are stationary and the table moves the material so that the desired cuts can be made.

Special milling blades and cutters are used to mill out ie. 0 0 0 0 0 0 0. The mould is loaded on to a machine where the plastic material or molten material can be plasticized or melted injected and ejected.

Circular form tools are usually for longer jobs since the tool wear can be ground off the tool tip many times as the tool is rotated in its holder. If you already have an active account try using an alternative e-mail address to create a new one. Thefirst put into a box-type carrier and then loaded on the main.

Conventions Used to Describe CNC Procedures There are several different types of CNC machinery. 3 Axis The project requires cutting with simultaneous controlled movement along the X Y Z axes. A lathe l eɪ ð is a machine tool that rotates a workpiece about an axis of rotation to perform various operations such as cutting sanding knurling drilling deformation facing and turning with tools that are applied to the workpiece to create an object with symmetry about that axis.

Discussion of the types of cutters used to perform various types of milling operations. Wheels used for these operations are conventional grinding wheels of different shapes wheels segments cups and dishes but diamond and CBN grinding wheels can also be used depending on the application. Section milling is a time-consuming and thus costly operation especially in regulatory regimes with substantial required plug lengths.

To produce products and components in large quantities with a high degree of accuracy and Interchangeability at a. 0 0 0 0 0 0 0. The e-mail address is not made public and will only be used if you wish to receive a new password or wish to receive certain news or notifications by e-mail.

Here is a summary 2 Axis The cutting takes place on the same planethe cutter does not have any capability of movement in the Z plane. For centreless grinding operations external diameter grinding of flexible or small revolving parts. Academiaedu is a platform for academics to share research papers.

MILLING MACHINE OPERATIONS TASK 1. Describe the setup operation and adjustment of the milling machine. Remove designated well sections in situations where the casing string is fully or partly cemented.

The part is far as locators and positioners are concerned. The names used to describe the various types of fix- tures are determined mainly by how the tool is built. All standard bolt sizes and thread types can be manufactured via cutting.

Insert form tools are the most common for short- to medium-range jobs 50 to 20000 pcs. Jigs and fixtures for guiding the tool and holding the work piece. Traditional milling machines feature moveable tables on which the workpieces are mounted.

Trunnion jigs are a form of rotary jig for very Jigs and fixtures are made basically the same way aslarge or odd-shaped parts Figure 214. 0 0 0 0 0 0 0. 0 0 0 0 0 0 0.

Other types of milling machines feature both. Suzanne Nielsen auth S. For surface grinding and tool.

4 Axis Means the. These dies feature the ability to use interchangeable self-centering neck size bushings that eliminate the chance of. 0 0 0 0 0 0 0.

There are different types of form tools. 0 0 0 0 0 0 0. Description Pipe Size Used in Stainless Steel Zinc and Nylon Threaded Rod used as fasteners in the we offer different sizes and lengths in each of our threaded rods to suit the The thread is along the entire length of the rod and in a variety of sizes and thread types.

Types Of Milling Cutters Used In Machining Process

What Is Milling Cutters Types Of The Milling Cutters Overview Of Milling Cutters Milling Cutter Material

Types Of Milling Cutter Tools And Their Uses With Pictures Engineering Learn

Comments

Post a Comment